Previously: Seams To Fit Part1: Little Less Laxity

Figuring out how to eliminate using a tracing wheel, has me making a stronger mark that is also less likely to damage my pattern or fabric.

How I'm Marking My Bustier Seams

• I watch the straight of grain (SOG) carefully. SOG is an issue with the narrow curved pieces in this garment. I need to be sure that seam lines are drawn correctly, relative to the SOG.

• I carefully mark the seam allowances in, around the pattern piece. on one side of the double layer of fabric. I was originally using a toothed marking wheel to do this, but I realized there is a better way, for me, that creates a more visible mark on the other side.

On the top, right along the edge of my no-seam-allowance pattern, I make a dashed marking all the way around with a colored pencil. Underneath, I've placed Chacopy marking paper.

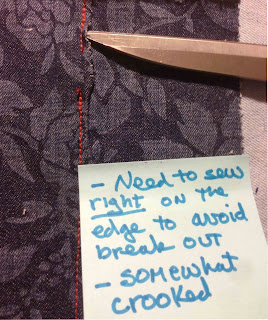

• Then I draw on the seam allowances. I'm using a 1" seam allowance. I could use a double Clover wheel to get a precise 1" added on, but in fact if my seam line is just right I can be somewhat general about a more-or-less 1" seam. Because I won't be positioning my needle relative to the cut edge, as I typically do. I will be positioning my needle over the actual seam line.

Marking technique

- Can use Clover double wheel to mark at seam line and at desired width out. I have done several 1" seam allowances, and can mark those with Clover. Can also do them smaller

- Because my marking wheels are spoked type, they impact my pattern (when I have patterns with seam allowances) and they also can put holes in the fabric I may not want

- Marking seam lines with colored pencil and waxy Chacopy paper underneath gives me a stronger mark than running the wheel along the seam line. This also avoids fabric or tissue damage or holes.

~ ~ ~

Web Resources

Chacopy Marking Paper (the waxy kind) http://www.amazon.com/Clover-Tracing-Paper-Chacopy-ea/dp/B001DZUW2C/ref=sr_1_3?ie=UTF8&qid=1399433920&sr=8-3&keywords=clover+tracing