Using pin techniques to join sections of my bustier precisely.

|

| The outer shell of my Bustier is coming along Too bad I can't just pin it to myself and head out the door |

Seams To Fit Part 1: A Little Less Laxity

Seams To Fit Part 2: Making My Mark

Seams To Fit Part 3: More Power to Interlining!

In my last "Seams To Fit" posting, I described how I used stitching marks on my interlining pieces to define the stitching lines on the fashion fabric it's backing. In both part 2 and part 3, I described how I made sure the fashion fabric was matched up properly.

Now that I was getting ready to sew each bodice piece together, I began to think of each piece as more of a section. That section is composed of one appropriately shaped piece of fashion fabric (the denim that shows on the outside of the bustier in my case) backed by an equivalently shaped interlining (a blue plaid cotton flannel). When it's prepped, one section is like one pattern piece.

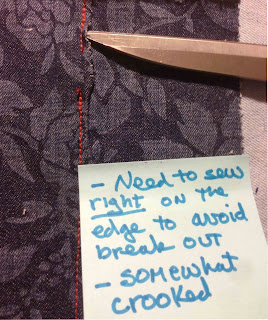

At this point in the process, I needed a way to join the stitching lines of each section precisely to it's neighboring section. When working on doing the same operation on the inner fitting shell of the bustier (then I was joining the cutil/lining pieces together) I'd found this to be rather challenging. I was constantly turning the sections over and finding that the pins weren't going through into the stitching lines.

|

| I marked the stitching lines all the way around each section with pins, using the stitching lines marked on the interlining |

When I laid, for example, piece 1a next to 1b, putting the fashion fabric (right sides) together, I now had pins on either seam line. I moved down the marked/pinned stitching lines pinning in the direction of the seam. As I moved, I worked another pin from one side of the stitching lines into the set on the other section. My fingers could feel that the pins were marrying up. I could, and did, still flip the sections back and forth, but it went a lot more easily than it had in the inner shell.

|

| The only Photoshopping I did was to change the fabric of my dress form, and swap the real background for my little gingham and scissors creation:-) |

The proof is in the denim pudding. My bustier's outer shell is coming along and fitting snug and right.

The fitting shell that goes below will provide the support the garment needs to allow the garment to leave my dress form and head out into the world.

Figuring out techniques for sewing seams precisely is one of those thing that keeps me...

Enchanted by Sewing!

~ ~ ~

Web Resources

My Pinterest Bustiers Board